Copper Ore Processing

2025年2月28日

Feldspar Processing

2025年2月28日

Copper Ore Processing

2025年2月28日

Feldspar Processing

2025年2月28日

Slag Processing

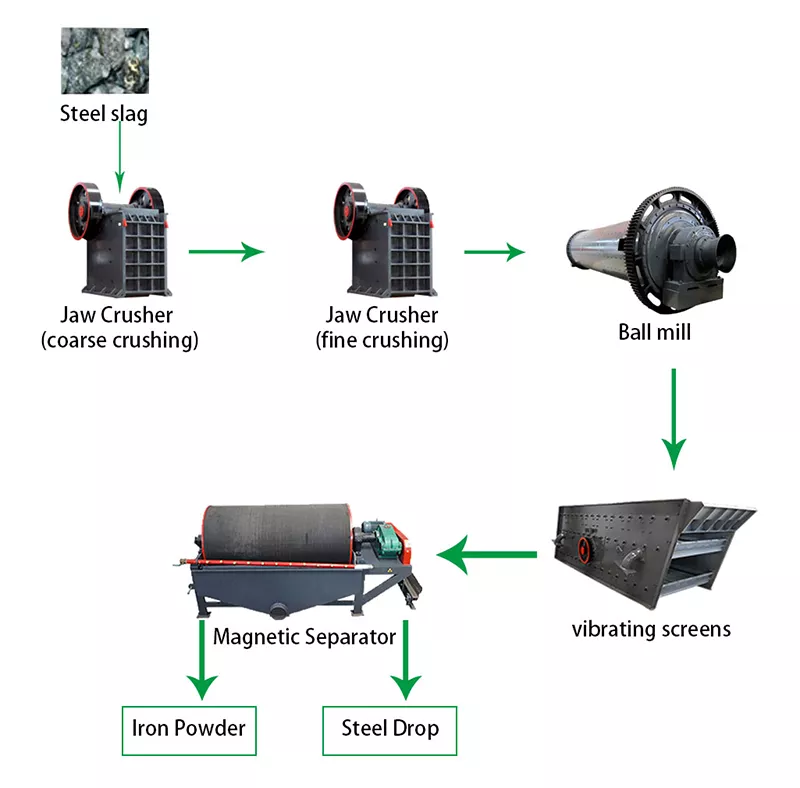

Steel Slag Processing Plant

-

1. Steel Slag Crushing

After the initial crushing by a jaw crusher, the steel slag is reduced to a size smaller than 60 mm. Then, the crushed steel slag is conveyed to a vibrating screen, where steel slag particles larger than 25 mm in diameter are transported to a cone crusher for secondary crushing, resulting in a particle size smaller than 25 mm. -

2. Steel Slag Grinding

In this step, we utilize a steel slag rod mill to grind the crushed steel slag, ensuring uniformity of the final product. If a powdered steel slag product is required, a combination of rod mill and vertical roller mill or vertical roller mill and ball mill can be selected. This step can be equipped with a dust collector for dust removal operations, collecting the ground dust. -

3. Steel Slag Separation

Steel slag separation typically employs magnetic separation, aiming to extract useful iron metals from the slag.

Both steel particles and iron powder in the steel slag exhibit magnetism. Therefore, magnetic separators are used to further purify the steel slag, obtaining a mixture of steel particles and iron powder, as well as waste residue.

In addition to magnetic separation, utilizing shaking tables for gravity separation of steel slag can also achieve high recovery rates of iron concentrates. -

4. Particle Classification

Using a vibrating screen to sieve metal iron particles of various sizes allows for the classification of steel particles and iron powder into coarse, medium, fine, and ultrafine grades, depending on the product's intended application.

Steel Slag Recycling for Sustainable Reuse

-

As a significant source of secondary resource utilization, metals from recycled steel slag are used for steel production or other metal products, while the non-metallic portion is utilized in cement production, road construction, fill materials, and more.

-

1. Smelting

Recycled steel slag is used as a smelting solvent in factories, replacing traditional limestone to improve smelting efficiency and recover a large amount of metal iron and other useful elements. -

2. Cement production

Steel slag exhibits Portland cement clinker characteristics, enhancing cement strength and durability when used as a mineral admixture, leading to zero-emission cement. -

3. Concrete production

Steel slag is increasingly replacing aggregates in concrete production due to natural resource depletion, resulting in concrete with superior mechanical properties and durability compared to traditional mixes. -

4. Road construction

Using processed steel slag as road base fill or pavement material can enhance the load-bearing capacity and durability of roads. -

5. Agricultural applications

Some components in steel slag are beneficial to soil, making it suitable for producing fertilizers and soil conditioners to promote plant growth.

PROFESSIONAL SERVICES

RECOMMEND EQUIPMENT

WHAT ELSE CAN I DO FOR YOU

ZHIJIAN

Sales Manager

Phone:+86-17621148835

[email protected]

What else can I do for you!