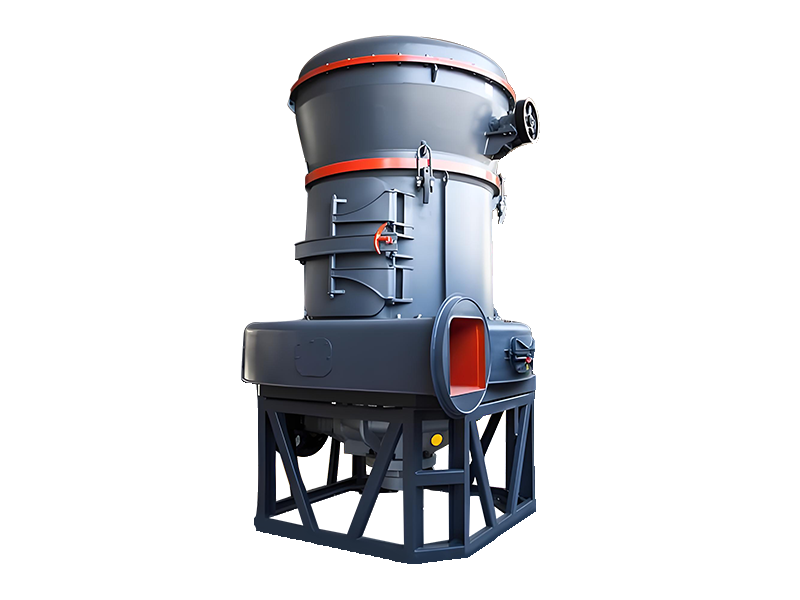

Ball Mill

2025年4月1日

Cement mill

2025年4月1日

Ball Mill

2025年4月1日

Cement mill

2025年4月1日

Highlights

Better Grinding Efficiency

Superior Sand-Making Capability

Energy-Saving Design

Strong Wear Resistance

Wide Application Range

Easy Maintenance & Operation

Working Principle

Feeding

Rod Movement

Line Contact Grinding

Particle Size Reduction

Discharge of Material

Technical Specs

| Model | Cylinder Diameter (mm) | Cylinder Length (mm) | Motor Model | Motor Power(kW) | Motor Rotating Speed (r/min) | Length (mm) | Width (mm) | Height (mm) | Capacity (t/h) | Effective Volume (m3) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MBY 0918 | 900 | 1800 | Y225M-8 | 22 | 730 | 4980 | 2370 | 2020 | 0.62~3.2 | 0.9 | 5700 |

| MBY 0924 | 900 | 2400 | Y250M-8 | 30 | 730 | 5670 | 3280 | 2020 | 0.81~4.3 | 1.2 | 5880 |

| MBY 1224 | 1200 | 2400 | Y280M-8 | 45 | 730 | 6450 | 2800 | 2500 | 0.4~4.9 | 2.28 | 12308 |

| MBYg 1530 | 1500 | 3000 | JR117-8 | 80 | 725 | 7253 | 3070 | 2280 | 2.4~7.5 | 5 | 21210 |

| MBYg 2130 | 2100 | 3000 | JR136-8 | 180 | 735 | 8122 | 4220 | 3073 | 14~35 | 9 | 42123.5 |

| MBYg 2136 | 2100 | 3600 | JR137-8 | 210 | 735 | 8958 | 4320 | 3025 | 43~61 | 10.8 | 45800.5 |

| MBYg 2736 | 2700 | 3600 | JR158-8 | 380 | 743 | 10764 | 5750 | 3620 | 32~86 | 17.7 | 90441 |

| MBY 2740 | 2700 | 4000 | TDMK400-32 | 400 | 187.5 | 12300 | 5700 | 4700 | 43~110 | 20.4 | 75000 |

| MBY 3040 | 3000 | 4000 | JR1510-8 | 570 | 740 | 9800 | 3900 | 3900 | 54~135 | 26 | 90000 |

| MBY 3245 | 3200 | 4500 | TDMK800-36 | 800 | 167 | 14600 | 7000 | 5300 | 64~180 | 31 | 113000 |

| MBY 3645 | 3600 | 4500 | TDMK1250-40 | 1250 | 150 | 15200 | 8800 | 6800 | 80~230 | 41.8 | 139000 |

| MBY 3654 | 3600 | 5400 | TDMK1600-40 | 1600 | 150 | 15900 | 8800 | 6800 | 100~250 | 49.7 | 150000 |

FAQ

If you encounter any problems while using our crushers, sand makers, grinding mills or mobile crushers and other mining equipment, or have any questions about equipment selection, operation and maintenance, troubleshooting, etc., you are welcome to leave a message here for consultation.

Job Position

Comments from Engineers

RECOMMEND EQUIPMENT

PROFESSIONAL SERVICES

WHAT ELSE CAN I DO FOR YOU

ZHIJIAN

Sales Manager

Phone:+86-17621148835

[email protected]

What else can I do for you!