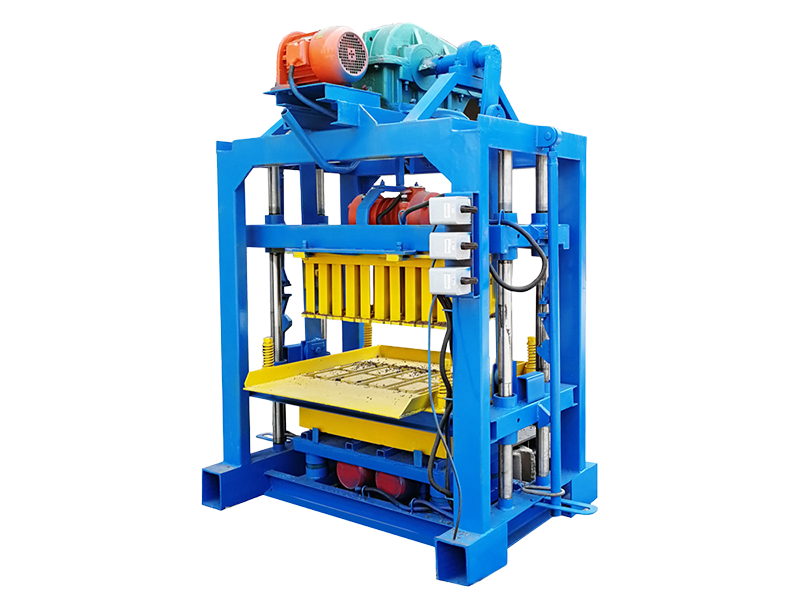

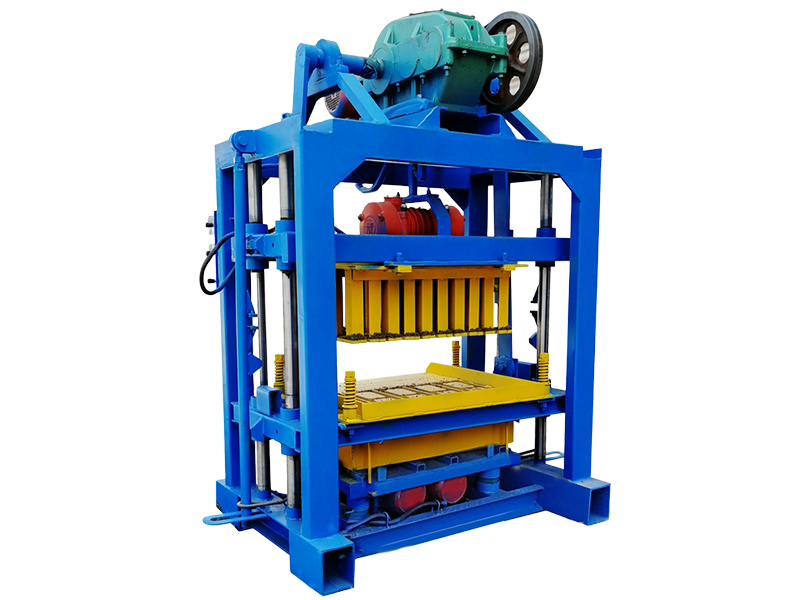

QTJ4-18 Hydraulic Automatic Block Machine

2025年4月8日

QTJ4-25D Automatic Block Machine

2025年4月8日

QTJ4-18 Hydraulic Automatic Block Machine

2025年4月8日

QTJ4-25D Automatic Block Machine

2025年4月8日

Highlights

Simple Structure and Reliable Performance

High Efficiency and Reduced Labor

Versatile and Energy-Efficient

Noise and Vibration Reduction

Environmentally Friendly

Low Investment, Fast Return

Working Principle

Material Feeding

Mold Filling

Compaction

Brick Formation

Brick Demolding

Curing

Gallery

Technical Specs

| Voltage | 220-440v single or 3phase 50/60HZ | ||

|---|---|---|---|

| Power | 9.6kw | ||

| Forming Cycle | 40S | ||

| Weight | 1200kg | ||

| Dimension | 1650x1150x2000mm | ||

| Pallet size | 850x450x20mm | ||

| Productivity | |||

| Size(LxWxH) | Pcs/Mould | Pcs/hour | Pcs/ 8 Hr |

| 400X200X200 | 4 | 360 | 2880 |

| 400X150X200 | 5 | 450 | 3600 |

| 400X125X200 | 6 | 540 | 4320 |

| 400X100X200 | 7 | 630 | 5040 |

| 200X100X60 | 14 | 1260 | 10080 |

| 200X160X60 | 8 | 720 | 5760 |

| 225X112.5X60 | 9 | 810 | 6480 |

FAQ

If you encounter any problems while using our crushers, sand makers, grinding mills or mobile crushers and other mining equipment, or have any questions about equipment selection, operation and maintenance, troubleshooting, etc., you are welcome to leave a message here for consultation.

Job Position

Comments from Engineers

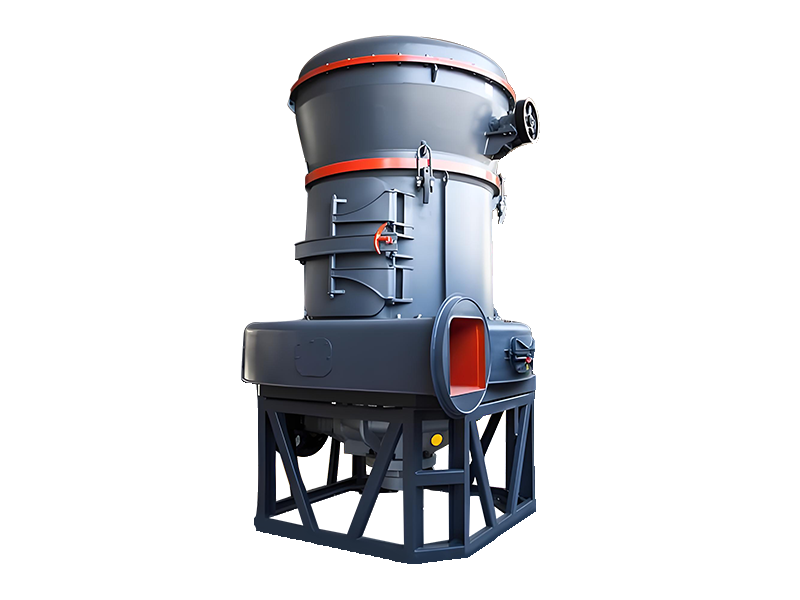

RECOMMEND EQUIPMENT

PROFESSIONAL SERVICES

WHAT ELSE CAN I DO FOR YOU

ZHIJIAN

Sales Manager

Phone:+86-17621148835

[email protected]

What else can I do for you!