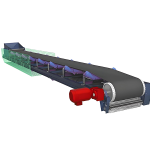

B Belt Conveyor

2025年4月8日

DMC Pulse Jet Dust Collector

2025年4月8日

B Belt Conveyor

2025年4月8日

DMC Pulse Jet Dust Collector

2025年4月8日

Highlights

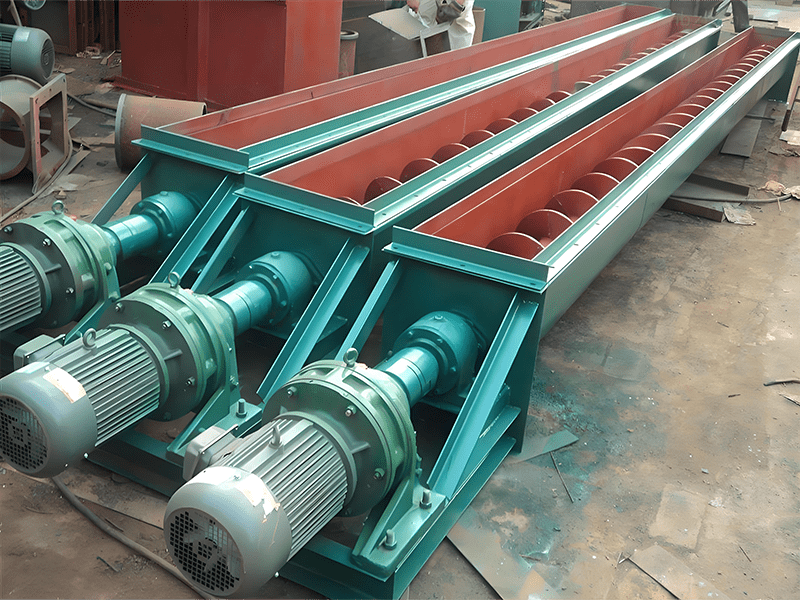

Compact and Simple Design

Efficient Material Transport

Versatile Applications

Customizable Length and Angle

Sealed Operation

Durable Construction

Working Principle

Material Feeding

Screw Rotation Begins

Material Engagement

Forward Conveying

Discharge of Material

Return and Continuity

Technical Specs

| Specification model | LS100 | LS160 | LS200 | LS250 | LS315 | LS400 | LS500 | LS630 | |

|---|---|---|---|---|---|---|---|---|---|

| Spiral diameter | D(mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 |

| pitch | P(mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 |

| Conveying capacity | n(r/min) | 140 | 112 | 100 | 90 | 80 | 71 | 63 | 50 |

| Q(m3/h) | 2.2 | 7 | 13 | 22 | 31 | 62 | 98 | 140 | |

| n(r/min) | 112 | 90 | 80 | 71 | 63 | 56 | 50 | 40 | |

| Q(m3/h) | 1.7 | 6 | 10 | 18 | 24 | 49 | 78 | 112 | |

| n(r/min) | 90 | 71 | 63 | 56 | 50 | 45 | 40 | 32 | |

| Q(m3/h) | 1.4 | 5 | 8 | 14 | 19 | 39 | 62 | 90 | |

| n(r/min) | 71 | 50 | 50 | 45 | 40 | 36 | 32 | 25 | |

| Q(m3/h) | 1.1 | 3.1 | 6.2 | 11 | 15.4 | 31 | 50 | 77 |

FAQ

If you encounter any problems while using our crushers, sand makers, grinding mills or mobile crushers and other mining equipment, or have any questions about equipment selection, operation and maintenance, troubleshooting, etc., you are welcome to leave a message here for consultation.

Job Position

Comments from Engineers

RECOMMEND EQUIPMENT

PROFESSIONAL SERVICES

WHAT ELSE CAN I DO FOR YOU

ZHIJIAN

Sales Manager

Phone:+86-17621148835

[email protected]

What else can I do for you!