Iron Ore Processing

2025年2月28日

Copper Ore Processing

2025年2月28日

Iron Ore Processing

2025年2月28日

Copper Ore Processing

2025年2月28日

Gold Ore Processing

Gold Ore Processing Plant

-

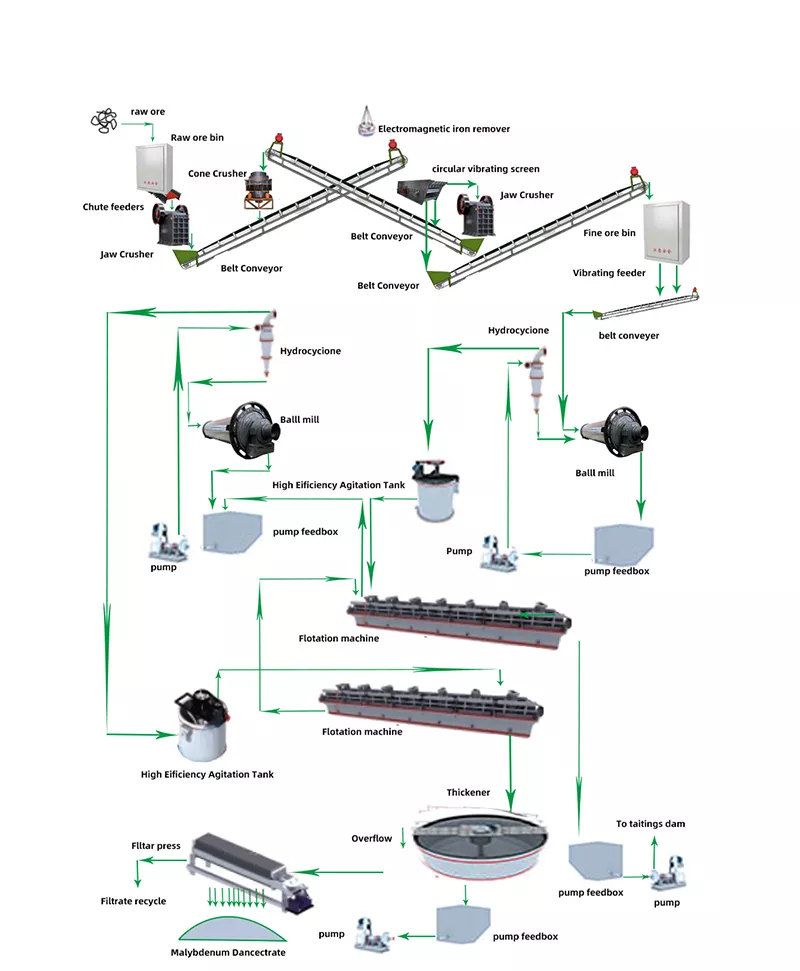

Step 1: Crushing

Due to the raw ore size being large, it is necessary to be crushed into suitable particles. The loader sends raw ore into a vibrating feeder, which feeds material evenly to a jaw crusher for the primary crushing process. In an ore beneficiation plant, one important rule is to crush more and grind less. If necessary, a cone crusher or hammer crusher could be added as a second crushing process to get suitable particles. Machine list: hopper, vibrating feeder, jaw crusher, cone crusher or hammer crusher (optional) -

Step 2: Grinding

After crushing, the material goes into a ball mill via feeder for fine size grinding. The grinding process needs to be selected via professional equipment, such as a mixing tank, flotation machine, shaking table, spiral chute, etc. Then the qualified concentrate powder from the ore is stocked in a settling pond. Machine list: mixing tank, flotation machine, magnetic separator, centrifugal gold machine, shaking table, etc. -

Remarks:

Due to various constraints, there are always some residual moisture in the ore powder, concentrate dehydration process could be added.

This step could meet the requirements of transportation and smelting, etc.

Gold Ore Processing Plant

-

Gold Ore Beneficiation Overview

Gold ore beneficiation process includes gravity separation and flotation process, gold CIP, CIL process, and gold heap leaching, all of which can realize high-efficiency recovery of gold. The beneficiation process and relative equipment are chosen according to the nature of the gold ore. Baichy could provide you with a complete set of gold processing solutions and equipment according to the specific types of gold mines. -

1. Alluvial / Placer Gold Process

The gold concentrate of placer gold ore has a high content and mostly exists in the form of sand grains. Therefore, gravity separation is often used when sorting. After pretreatment, desliming, and washing of ore, coarse gold ore particles can be directly obtained by gravity separation process. Gravity separation is an effective and economical treatment method in placer gold ore beneficiation. -

2. Rock Gold Process

The hard rock gold processing plant is very efficient with a recovery rate of 95% by removing most of the individual crude gold ore through gravity separation process primarily. It commonly uses processes such as gold flotation, CIL (Carbon-in-Leach), and CIP (Carbon-in-Pulp). -

3. Associated Gold Mine Process

This includes depleted sulfide gold ore, polysulfide gold ore, gold-bearing polymetallic ore, telluride-bearing gold-gold ore, and gold-bearing copper ore. The gold beneficiation process involves gravity separation, flotation, magnetic separation, CIP, CIL, and other combined methods. Flotation is often used to treat gold-bearing ores of sulfide minerals to quickly collect gold-bearing sulfide concentrates for efficient comprehensive utilization.

PROFESSIONAL SERVICES

RECOMMEND EQUIPMENT

WHAT ELSE CAN I DO FOR YOU

ZHIJIAN

Sales Manager

Phone:+86-17621148835

[email protected]

What else can I do for you!