Slag Processing

2025年2月28日

Fluorite Flotation

2025年2月28日

Slag Processing

2025年2月28日

Fluorite Flotation

2025年2月28日

Feldspar Processing

Feldspar Processing Plant

-

According to different feldspar mineral types and ore properties, Dingbo customizes a series of feldspar processing technology, including magnetic separation, flotation, gravity separation and combined technology. So as to achieve the removal of mica mineral impurities, etc., to obtain potassium and sodium feldspar concentrate, aiming to obtain high-grade feldspar concentrate.

-

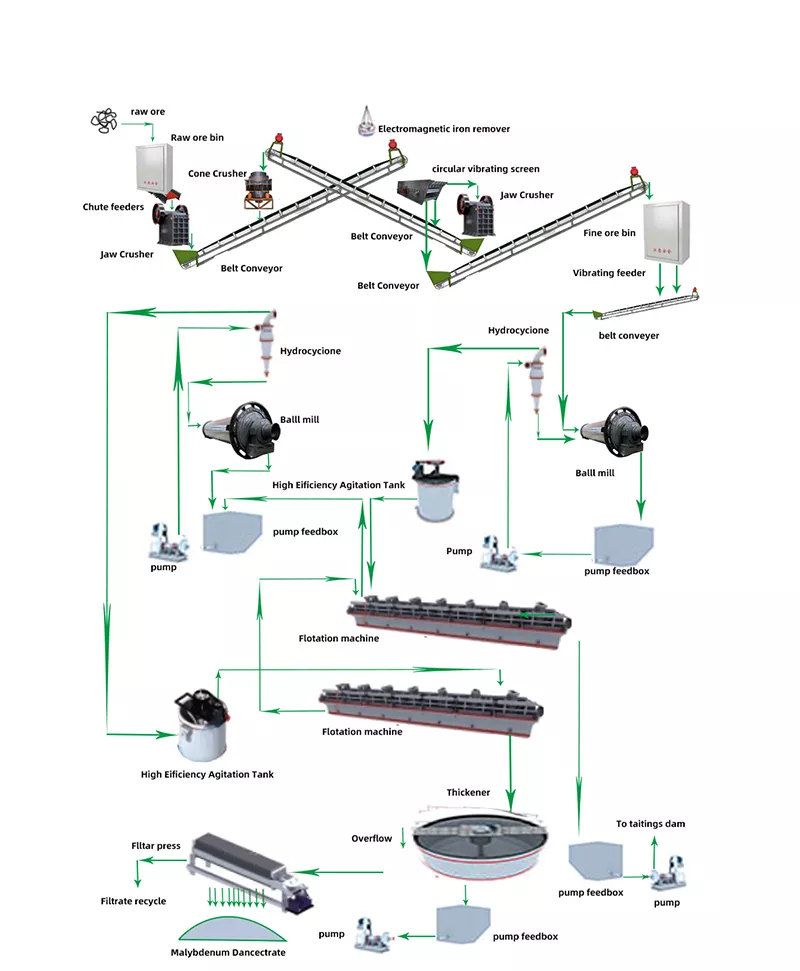

Crushing & Grinding

Large particle size of feldspar ore firstly should be crushed by jaw crusher to qualified particle size, thus to guarantee the grinding quality and protect ball mill. Ball mill is applied into the second stage - grinding, Xinhai has wet grate ball mill and wet grate overflow ball mill which can perfectly grind feldspar ore into qualified particle size. -

Flotation Separation

With experience in Feldspar flotation separation, flotation cell is the main mining machines in this part, the slurry dealt with agential through milling and inflating can make certain particles of it selectively attaches to the bubbles to achieve mineral separation. Besides flotation machines, other mining machines also will be used in the stages, if you want to know more, just click the online service. -

Desliming

Qualified grinding materials are fed into desliming bucket for desliming operation. -

Magnetic Separation

After desliming, the ore enters the two-stage magnetic separation operation of low intensity magnetic + high intensity magnetic to remove magnetic substances in the ore.

PROFESSIONAL SERVICES

WHAT ELSE CAN I DO FOR YOU

ZHIJIAN

Sales Manager

Phone:+86-17621148835

[email protected]

What else can I do for you!