DBMQ Semi-mobile Crushing Station

2025年2月20日

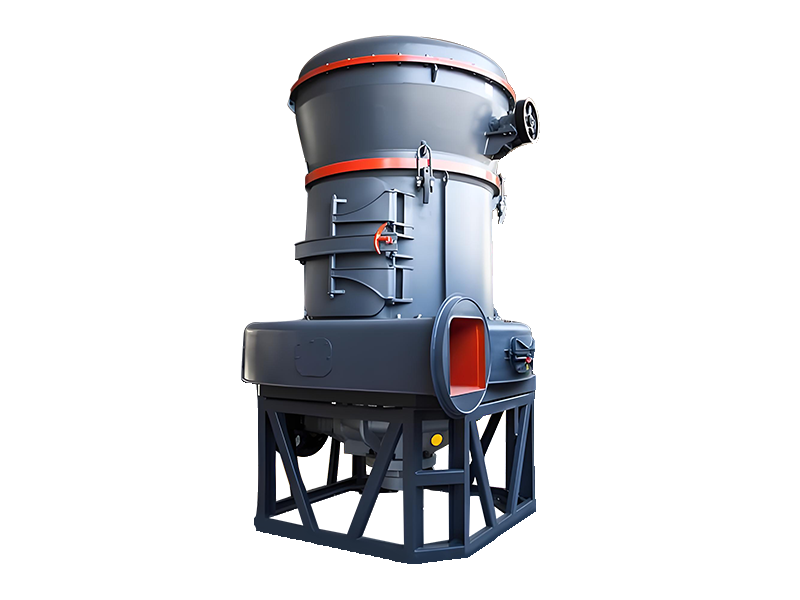

YGM Raymond Mill

2025年2月21日

DBMQ Semi-mobile Crushing Station

2025年2月20日

YGM Raymond Mill

2025年2月21日

Highlights

High Grinding Efficiency

Adjustable Particle Size Control

Compact Design

Low Maintenance

Working Principle

Feeding Mechanism

Grinding Rollers and Tracks

Adjustable Grinding Pressure

Dust Extraction System

Recycling of Unused Material

Energy Efficiency

Technical Specs

Dingbo vertical mills feature a rational and reliable structure as well as an advanced process that combines drying, grinding, separation and conveying, which is suitable for grinding materials of different types and sizes.

| Model | Yield (t/h) | Grinding Plate Diameter (mm) | Grinding Path Diameter (mm) | Material Moisture (%) | Raw Material Fineness (%) | Raw Material Moisture (%) | Main Motor Power (kW) |

|---|---|---|---|---|---|---|---|

| DBGM1300 | 20-25 | 1870 | 1300 | <10% | R0.08≤12% | ≤1% | 200 |

| DBGM1500 | 26-34 | 2180 | 1500 | <10% | R0.08≤12% | ≤1% | 280 |

| DBGM1700 | 40-50 | 2400 | 1700 | <10% | R0.08<12% | ≤1% | 400 |

| DBGM1900 | 60-70 | 2680 | 1900 | <10% | R0.08<12% | ≤1% | 500 |

| DBGM2200 | 85-110 | 2900 | 2200 | <10% | R0.08<14% | ≤1% | 800 |

| DBGM2400 | 95-130 | 3140 | 2400 | <10% | R0.08<14% | ≤1% | 900 |

| DBGM2800 | 120-160 | 3300 | 2800 | <10% | R0.08<14% | ≤1% | 1250 |

| DBGM3400 | 190-240 | 4560 | 3400 | <10% | R0.08<15% | ≤1% | 1800 |

FAQ

If you encounter any problems while using our crushers, sand makers, grinding mills or mobile crushers and other mining equipment, or have any questions about equipment selection, operation and maintenance, troubleshooting, etc., you are welcome to leave a message here for consultation.

Job Position

Comments from Engineers

RECOMMEND EQUIPMENT

PROFESSIONAL SERVICES

WHAT ELSE CAN I DO FOR YOU

ZHIJIAN

Sales Manager

Phone:+86-17621148835

[email protected]

What else can I do for you!