Gold Ore Processing

2025年2月28日

Slag Processing

2025年2月28日

Gold Ore Processing

2025年2月28日

Slag Processing

2025年2月28日

Copper Ore Processing

Copper Ore Processing Plant

-

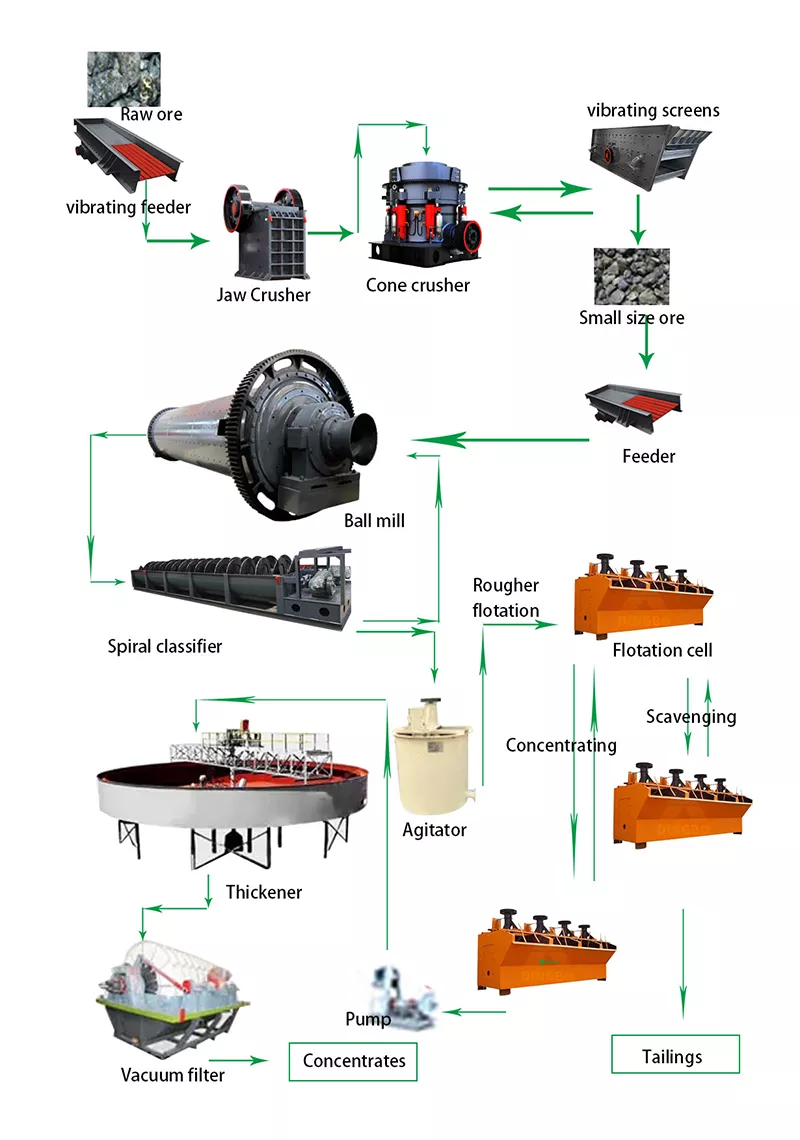

1. Raw Copper Ore Crushing

The copper ore in the quarry is transported to the transit silo, which is then evenly fed to the jaw crusher by the vibrating feeder for primary crushing. According to “more crushing and less grinding”, the crushed copper ore goes into a fine jaw crusher for more crushing. This is prepared for the milling process. -

2. Copper Ore Grinding

After fine crushing, the copper particles are sent into the ball mill for grinding. For later flotation, a spiral classifier is needed to classify and screen the ground copper ore. The materials that meet the requirements can enter into the next process for mineral processing, and the copper powder that does not meet the requirements will be sent back to the ball mill for grinding again. -

3. Copper Ore Flotation for Concentrating

The qualified copper slurry is fed into the mixing tank, and the corresponding chemical agents are added to make a reaction. The slurry goes into the flotation cell for processing. The flotation process includes roughing, scavenging, and concentrate selecting. In the froth flotation process, some agents will be used to select copper, such as lime to give a basic pH, pine oil to make bubbles, alcohol to strengthen the bubbles, and a collector chemical, etc. Through a series of steps, the copper ore is concentrated, and the waste material that comes out of the bottom of the tanks is called tailings. -

4. Copper Ore Dehydration

Suspend the copper concentrate slurry in the thickener for full precipitation, and then high-grade copper concentrate powder can be obtained after dehydrating and drying through the dryer.

Copper Ore Beneficiation Process

-

Copper ore beneficiation is a process to extract copper from raw ores. Raw copper ore can be divided into three categories: copper oxide ore (azurite, cuprite, and malachite), copper sulfide ore (chalcopyrite, bornite, and chalcocite), and natural copper. Copper ore beneficiation process commonly includes gravity separation, flotation process, and magnetic separation.

-

Gravity Separation

The gravity separation method sorts minerals according to their relative density (usually called specific gravity). Currently, gravity separation is only used to select copper ores with coarser inlays and is especially suitable for copper oxide ores with higher density. -

Flotation Separation

Copper flotation process is based on the difference in the physical and chemical properties of the mineral surface, processed by the flotation agent, and the mineral is selectively attached to the bubbles to achieve the purpose of separation. The beneficiation of non-ferrous metal ores, such as copper sulfide ore, lead, zinc, sulfur, molybdenum, etc., is mainly treated by flotation process; some ferrous metals, rare metals, and some non-metallic ores, such as graphite ore, apatite, etc., are also treated using the copper flotation process.

The composition of copper ore is generally more complex, associated with more minerals, and it cannot use a simple method of leaching separation. It has priority flotation and mixed flotation. Preferential flotation is to float the useful minerals and then separate two or more of them. Mixed flotation is the flotation of a variety of useful minerals at the same time, then through other ways to separate again.

PROFESSIONAL SERVICES

RECOMMEND EQUIPMENT

WHAT ELSE CAN I DO FOR YOU

ZHIJIAN

Sales Manager

Phone:+86-17621148835

[email protected]

What else can I do for you!