Graphite Processing

2025年2月28日

Mobile Construction Waste Recycling Plant

2025年3月3日

Graphite Processing

2025年2月28日

Mobile Construction Waste Recycling Plant

2025年3月3日

Barite Processing

Barite Processing Plant

-

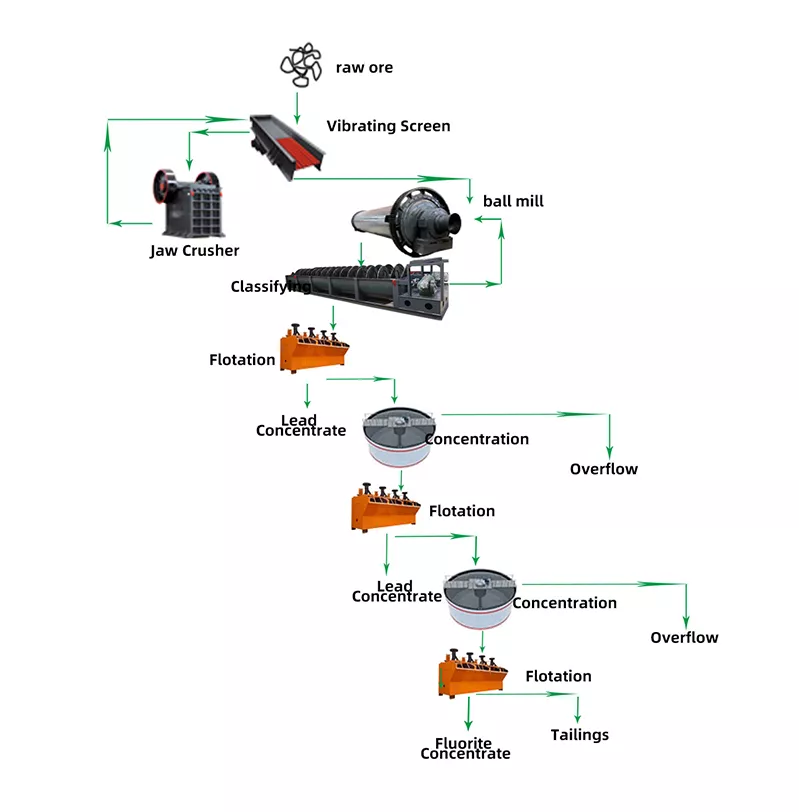

Gravity Separation

For the gravity separation of barite, the process of Dingbo is crushing, screening and jigging. Then the high grade (over 80%) concentrate will be produced. The jig is the main equipment for the separation and purification of barite ore, which is energy-saving, high efficiency, and environment protection.

In the process of crushing, Dingbo uses the jaw crusher and applies a two-stage crushing process. In the process of screening, Dingbo uses a simple and useful circular vibrating screen, which also has the features of large capacity, high efficiency, and convenient operation. It is very suitable for screening of barite ore.

In the process of jigging, Xinhai applies two kinds of jigs to respectively separate the coarse and fine granularity of barite material. -

Magnetic Separation

Zhijian usually applies wet magnetic separation to beneficiate some iron-bearing mineral, like siderite, which applies to barite ore that is used in barium-based medicine requiring low iron barite. -

Floatation

As for the barite with fine particle size and gravity tailings, Dingbo applies the process of floatation. According to the different adsorption manner, Dingbo uses some anionic collectors, like fatty acid alkyl sulfate, alkyl sulfonate, or cationic collector, like amide collectors to do the floatation for barite ore.

PROFESSIONAL SERVICES

RECOMMEND EQUIPMENT

WHAT ELSE CAN I DO FOR YOU

ZHIJIAN

Sales Manager

Phone:+86-17621148835

[email protected]

What else can I do for you!