物料测试

2025年3月12日

Rod Mill

2025年4月1日物料测试

2025年3月12日

Rod Mill

2025年4月1日

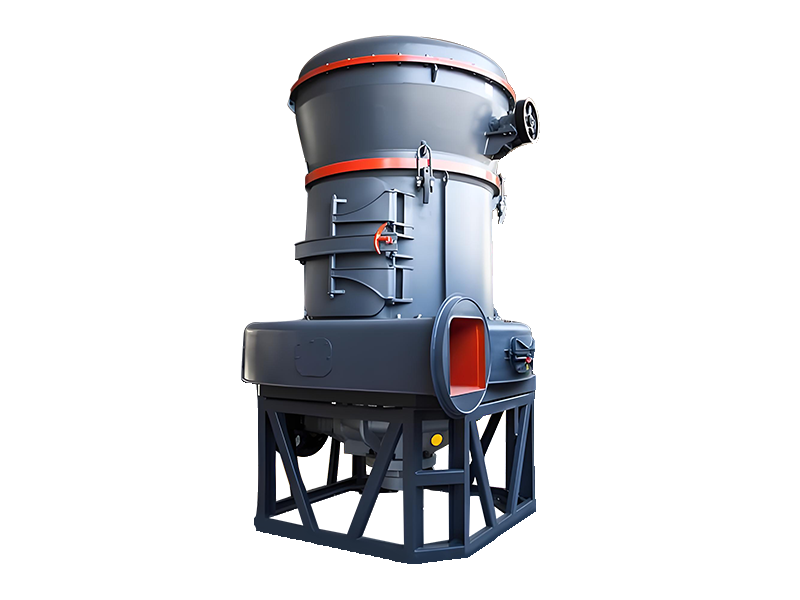

Highlights

High Efficiency

Energy-Saving Technology

Durable Construction

Easy Maintenance

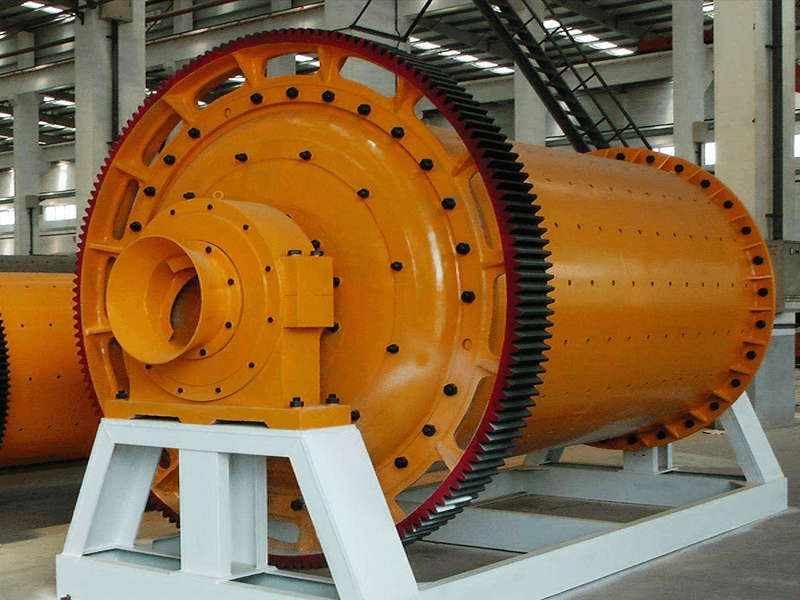

Working Principle

Feeding Material

Rotating Drum

Grinding Action

Adjustment of Particle Size

Energy Efficiency

Discharging Material

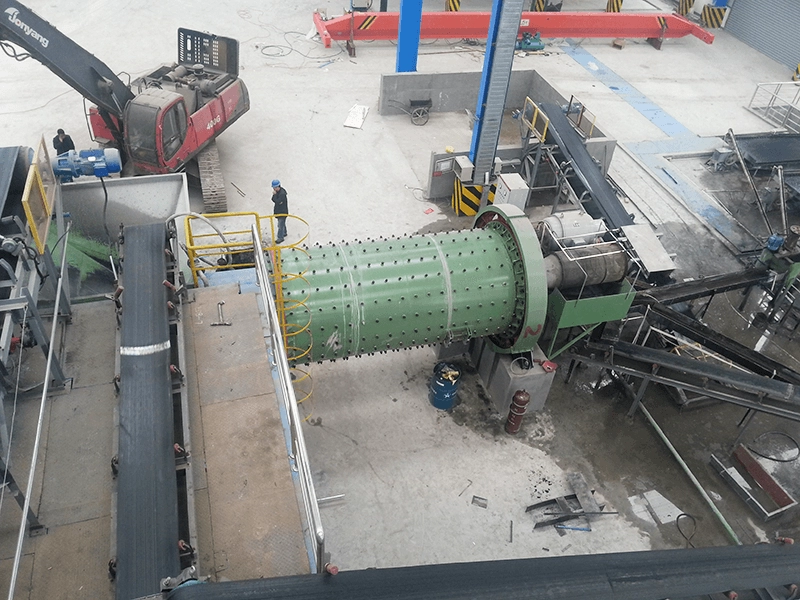

Gallery

Technical Specs

Model Cylinder rotary speed(r/min) Loading ball weight (t) Input size (mm) Discharge size (mm) Capacity (t/h) Motor power (kw) Weight (t)

Ф900×1800 39 1.5 ≤20 0.075-0.89 0.8-2 18.5 4.6

Ф900×3000 39 2.7 ≤20 0.075-0.89 45661 22 5.6

Ф1200×3000 36 3.5 ≤25 0.074-0.4 1.6-5 37 12.8

Ф1200×4500 32 5 ≤25 0.074-0.4 1.6-5.8 55 13.8

Ф1500×3000 27 7.5 ≤25 0.074-0.4 45693 75 15.6

Ф1500×5700 28 12 ≤25 0.074-0.4 3.5-6 130 24.7

Ф1830×3000 25 11 ≤25 0.074-0.4 45757 130 28

Ф1830×6400 24 21 ≤25 0.074-0.4 45854 210 34

Ф1830×7000 24 23 ≤25 0.074-0.4 45887 245 36

Ф2100×3600 23 19 ≤25 0.074-0.4 10-36 210 46

Ф2200×4500 21 27 ≤25 0.074-0.4 46014 280 48.5

Ф2200×6500 21 35 ≤25 0.074-0.4 14-26 380 52.8

Ф2200×7000 21 35 ≤25 0.074-0.4 15-28 380 54

Ф2200×7500 21 35 ≤25 0.074-0.4 15-30 380 56

Ф2400×4500 21 30 ≤25 0.074-0.4 18-45 320 65

Ф2400×8000 20 36 ≤25 0.074-0.4 20-48 410 81

Ф2700×3600 21 39 ≤25 0.074-0.4 19-75 400 83

Ф2700×4000 20 40 ≤25 0.074-0.4 20-78 400 85

Ф2700×4500 20 48 ≤25 0.074-0.4 22-85 430 89

Ф3200×4500 18 65 ≤25 0.074-0.4 29-140 800 137

Ф3200×5400 18 81.6 ≤25 0.074-0.4 30-180 800-1000 146

Ф3600×4500 17 88 ≤25 0.074-0.4 35-210 1000 190

Ф3600×6000 17 117 ≤25 0.074-0.4 38-240 1250-1500 220

Ф3600×8500 17 144 ≤25 0.074-0.4 45-260 1800 260

FAQ

If you encounter any problems while using our crushers, sand makers, grinding mills or mobile crushers and other mining equipment, or have any questions about equipment selection, operation and maintenance, troubleshooting, etc., you are welcome to leave a message here for consultation.

Job Position

Comments from Engineers

RECOMMEND EQUIPMENT

PROFESSIONAL SERVICES

WHAT ELSE CAN I DO FOR YOU

ZHIJIAN

Sales Manager

Phone:+86-17621148835

[email protected]

What else can I do for you!