150-220tph Sand making plant

2025年4月15日

Coal Powder Processing

2025年4月15日

150-220tph Sand making plant

2025年4月15日

Coal Powder Processing

2025年4月15日

Powder Grinding Plant

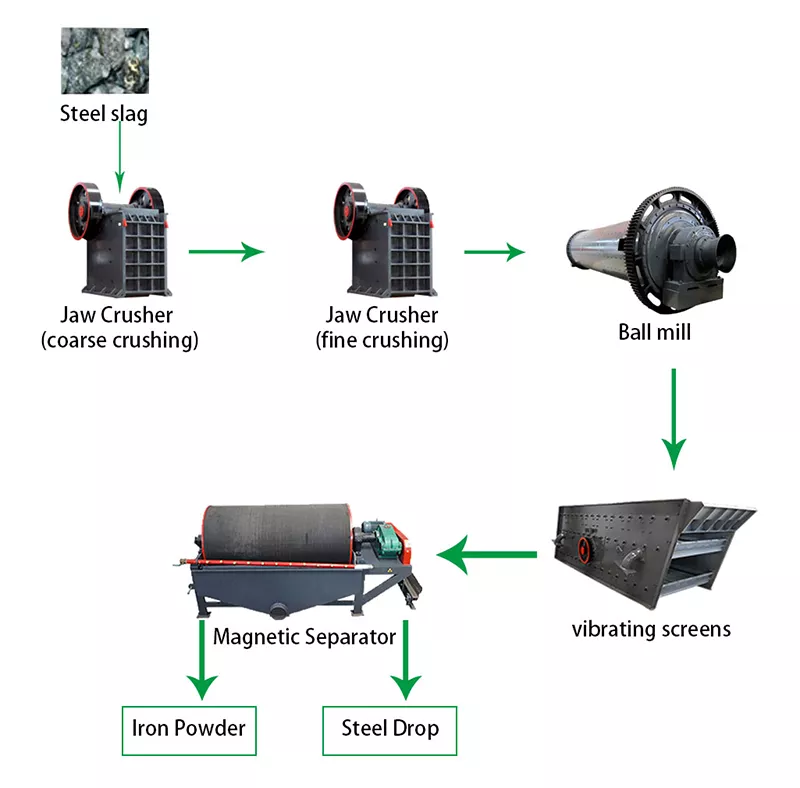

Basic process

-

Crushing

Crushing part of powder grinding line

The large stones or other minerals are sent to the jaw crusher by vibrating feeder for primary crushing into the required size (under the size of 25 or 30 mm).

Then the materials are sent into the stock bin by bucket elevator. -

Grinding

Grinding part of powder production line

The materials in the stock bin are uniformly transferred into the grinding machine by electric-magnetic vibrating feeder for further grinding (into the size of 80 to 3000 mesh).

The ground materials are conveyed by airflow and classified by the analyzer. -

Collecting

Collecting part of powder grinding line

After classifier, the powder met the requirements is collected by a powder collector and sent into another bin through the pipeline.

Advantages

- The grinding technology is very advanced, the machines equipped have high quality, reliable performance, high-cost performance, and durable service life.

- The grinding process is simple, the ore processing capacity is relatively large, and the output increases by more than 40%.

- The efficiency of the whole production line is extremely high, the operation process is very safe and stable, and the failure rate is extremely low.

- It has low energy and electricity consumption, little resource waste, little investment cost, and high profit.

- It has a good grinding effect and high powder yield. And the finished powder fineness is uniform with fewer impurities.

PROFESSIONAL SERVICES

RECOMMEND EQUIPMENT

WHAT ELSE CAN I DO FOR YOU

ZHIJIAN

Sales Manager

Phone:+86-17621148835

[email protected]

What else can I do for you!